hmmm......those big styrofoam gliders have wings. Course he's destroyed one of those...so I'm not sure the durability will work.

Wonder if I could shrink wrap it?

Evolution of a young hillclimber.

Re: Evolution of a young hillclimber.

Sachilles

02 Subaru impreza (Donut) #66

02 Subaru impreza (Donut) #66

-

Chief Geek

- Posts: 302

- Joined: Sun Feb 07, 2010 2:36 pm

- AntiSpam: No

Re: Evolution of a young hillclimber.

Seth

I'll bring one or two 6" x 12" x 48" blocks of EPS foam to Okemo for you two to do "wing development".

Because of what my company does, cutting a block into an airfoil-ish shape is a 5 minute job. If you're interested, let me know what shape you two have in mind? Maybe like this?

Paul

PS This offer is good for anyone, although, if you're too old to fit in the Racing Gator, I'm not going to make the pair of airfoil-shaped templates for you.

I'll bring one or two 6" x 12" x 48" blocks of EPS foam to Okemo for you two to do "wing development".

Because of what my company does, cutting a block into an airfoil-ish shape is a 5 minute job. If you're interested, let me know what shape you two have in mind? Maybe like this?

Paul

PS This offer is good for anyone, although, if you're too old to fit in the Racing Gator, I'm not going to make the pair of airfoil-shaped templates for you.

"Christina", New #13/#55x, '90 Miata: In progress

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

Re: Evolution of a young hillclimber.

That would be awesome Paul....let me figure out a better idea of the size needed.

Thank you.

Thank you.

Sachilles

02 Subaru impreza (Donut) #66

02 Subaru impreza (Donut) #66

-

Chief Geek

- Posts: 302

- Joined: Sun Feb 07, 2010 2:36 pm

- AntiSpam: No

Re: Evolution of a young hillclimber.

It's just 1 lb/cuft EPS so it won't be rated for speeds above Gator-velocity.

If you give me the pipe OD, I can cut the profile with round holes through the it's length so you can use roll-cage material (PVC pipe) as a spar. Honestly, I can do most anything you want so long as it's a 2-D profile. Over time, I bet we could make a great LMP1 body to create the worlds first Gator (of any scale) w/ down-force.

Paul

If you give me the pipe OD, I can cut the profile with round holes through the it's length so you can use roll-cage material (PVC pipe) as a spar. Honestly, I can do most anything you want so long as it's a 2-D profile. Over time, I bet we could make a great LMP1 body to create the worlds first Gator (of any scale) w/ down-force.

Paul

"Christina", New #13/#55x, '90 Miata: In progress

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

- Challenger392

- Posts: 254

- Joined: Tue Aug 14, 2012 11:52 pm

- AntiSpam: No

Re: Evolution of a young hillclimber.

You'd be supprised what properly supported EPS will take. If you shrink wrap it with RC plane "monokote" and have agood pplywood spar with proper mounting, I bet it could take speed at least for prototype purposes. Just out of curiosity how wide of a wing can you cut?Chief Geek wrote:It's just 1 lb/cuft EPS so it won't be rated for speeds above Gator-velocity

Luke Moultroup

Technical Support

Pratt & Whitney Engine Services

http://moultroupracing.blogspot.com/

2012 Dodge Challenger SRT8 392

1972 Dodge Challenger 318

2006 Jeep Grand Cherokee 5.7

2004 Mazda 6

Howe Modified

1989 Suzuki GSXR1100K

Technical Support

Pratt & Whitney Engine Services

http://moultroupracing.blogspot.com/

2012 Dodge Challenger SRT8 392

1972 Dodge Challenger 318

2006 Jeep Grand Cherokee 5.7

2004 Mazda 6

Howe Modified

1989 Suzuki GSXR1100K

Re: Evolution of a young hillclimber.

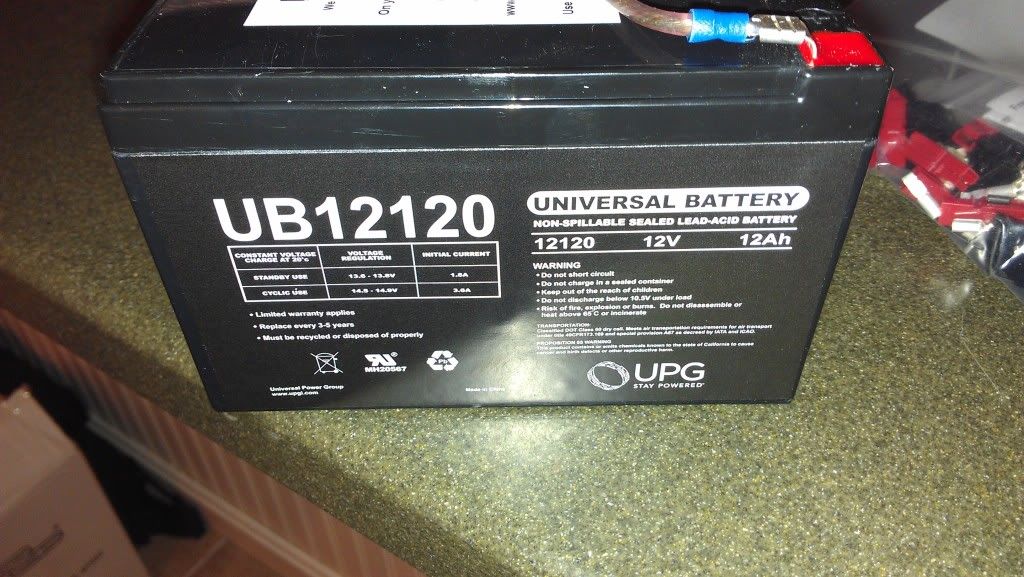

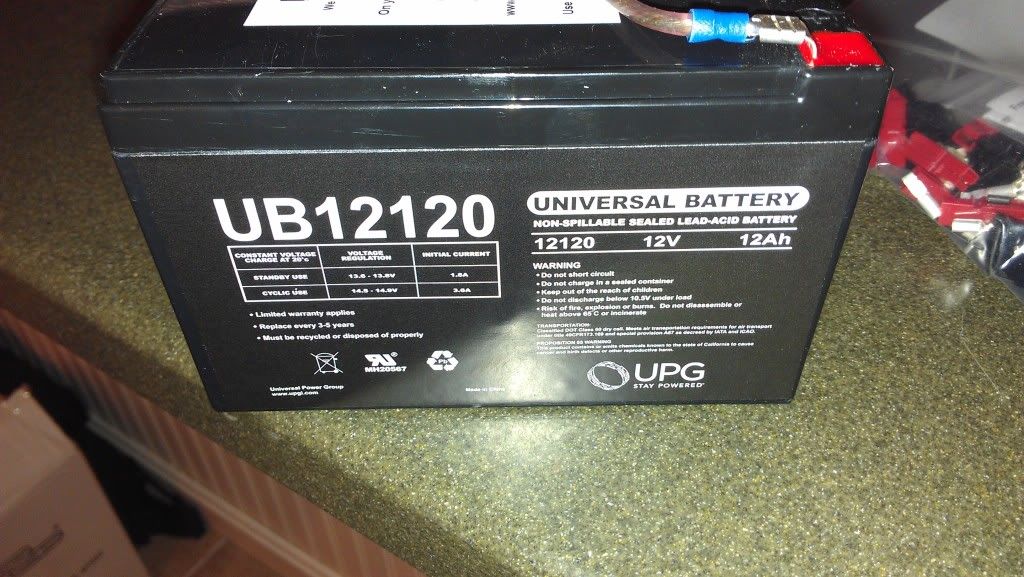

Time for a little work on the electrical system.

First up are some battery updates. We had been using some 12v sla type batteries, and they were 7.4 ah. Well they worked pretty well, but due to mistakes on my part storing the batteries over the winter, they seemed to have diminished capacity this summer in terms of endurance. We were lucky to get 5-10 minutes out of one, and their strength didn't quite seem up to task.

So ebay came to the rescue, and we bought 4 of these bad boys for about $80 shipped on ebay.

These are 12ah. First time out we got 30 minutes out of one, and parked it with plenty of good life left. We really don't want to kill the battery under load if we can avoid that.

Issue number 2 was improving power connections and replacing some rather thin wire. I had been using generic grote two pole connectors. My battery charger used them, and the local parts store sold pairs of the connectors pre-wired for cheap enough...so I had went with them. Well, the connectors and wiring just were not up to the task, causing the connectors to get hot, and start to get soft. Eventually, they'd connect even more poorly and get worse by the use.

I figured that better batteries would be wasted with the old connections. So I searched the internet for some better connectors, and came across the power pole connectors. I had used them when I was a kid on my radio control race cars and thought they were awesome then. I figured the 45 amp connectors would do the trick and ordered up a bunch. I also replaced the thin gauge wire with much thicker gauge wire scrounge up from some "monster cables".

I shortened wires where I could and eliminated crimps where practical, soldering what I could. I'm happy to report after our 30 minute lapping session, that there were no warm wires or any other wiring issues.

Now 30 minutes is a long time to wait around while you watch your son having all the fun driving the gator around the "track". I won't say it got boring, but it wasn't the most stimulating experience....so my mind began to wander a little.....then I realized I had my phone with me, and it has datalogging capability. By this time we were 25 minutes in to the session and I perceived that the battery could be weakening a little bit. However it was still better than the old ones. So I had Andrew come in for a pit stop and I installed the datalogger, and sent him on his way. I'm pleased to report that he was able to manage a peak of 11.74 mph in a gravity and wind aided sprint. On flat ground he was averaging 6 mph or so and about 3 mph on the uphill sections of our yard. He posted a maximum reading of 0.46 g on acceleration, given the grip of plastic tires its quite impressive. This is all on 12 volts.

This was some good progress I think. I may have to investigate the motors a little bit, sure look like the old motors I used in radio control cars back in the day. I'm betting I might be able to swap something a little faster than stock. They appear to have the same mounting setup. Of course I can up the voltage as well. Still trying to figure out the best way to skin the cat in that regards. It has a twin motor setup(one for each wheel). I'm thinking I may want to individually power each wheel.

So we now face the age old dilemma of getting a little more power hungry, knowing full well that more power means less reliability. What to do, what to do?

First up are some battery updates. We had been using some 12v sla type batteries, and they were 7.4 ah. Well they worked pretty well, but due to mistakes on my part storing the batteries over the winter, they seemed to have diminished capacity this summer in terms of endurance. We were lucky to get 5-10 minutes out of one, and their strength didn't quite seem up to task.

So ebay came to the rescue, and we bought 4 of these bad boys for about $80 shipped on ebay.

These are 12ah. First time out we got 30 minutes out of one, and parked it with plenty of good life left. We really don't want to kill the battery under load if we can avoid that.

Issue number 2 was improving power connections and replacing some rather thin wire. I had been using generic grote two pole connectors. My battery charger used them, and the local parts store sold pairs of the connectors pre-wired for cheap enough...so I had went with them. Well, the connectors and wiring just were not up to the task, causing the connectors to get hot, and start to get soft. Eventually, they'd connect even more poorly and get worse by the use.

I figured that better batteries would be wasted with the old connections. So I searched the internet for some better connectors, and came across the power pole connectors. I had used them when I was a kid on my radio control race cars and thought they were awesome then. I figured the 45 amp connectors would do the trick and ordered up a bunch. I also replaced the thin gauge wire with much thicker gauge wire scrounge up from some "monster cables".

I shortened wires where I could and eliminated crimps where practical, soldering what I could. I'm happy to report after our 30 minute lapping session, that there were no warm wires or any other wiring issues.

Now 30 minutes is a long time to wait around while you watch your son having all the fun driving the gator around the "track". I won't say it got boring, but it wasn't the most stimulating experience....so my mind began to wander a little.....then I realized I had my phone with me, and it has datalogging capability. By this time we were 25 minutes in to the session and I perceived that the battery could be weakening a little bit. However it was still better than the old ones. So I had Andrew come in for a pit stop and I installed the datalogger, and sent him on his way. I'm pleased to report that he was able to manage a peak of 11.74 mph in a gravity and wind aided sprint. On flat ground he was averaging 6 mph or so and about 3 mph on the uphill sections of our yard. He posted a maximum reading of 0.46 g on acceleration, given the grip of plastic tires its quite impressive. This is all on 12 volts.

This was some good progress I think. I may have to investigate the motors a little bit, sure look like the old motors I used in radio control cars back in the day. I'm betting I might be able to swap something a little faster than stock. They appear to have the same mounting setup. Of course I can up the voltage as well. Still trying to figure out the best way to skin the cat in that regards. It has a twin motor setup(one for each wheel). I'm thinking I may want to individually power each wheel.

So we now face the age old dilemma of getting a little more power hungry, knowing full well that more power means less reliability. What to do, what to do?

Sachilles

02 Subaru impreza (Donut) #66

02 Subaru impreza (Donut) #66

-

Chief Geek

- Posts: 302

- Joined: Sun Feb 07, 2010 2:36 pm

- AntiSpam: No

Re: Evolution of a young hillclimber.

Those connectors are quite good, certainly higher capacity than the spade connectors to the battery.

I also raced RC cars competitively and those were the only connectors (beyond directly soldered wires) that held up to the 100+ amps we'd put through them.

You two are welcome to any of my state-of-the-art-for-1995 RC racing stuff. I have a couple of 540-sized motors that consumed about 800W @ 7V (for 5 minutes at a time). Although... Seth may get tired of doing a full motor rebuild for every 5 minutes of run time.

About the foam, the biggest thing I can get is 4ft x 24ft by 38in. The biggest blocks I can get for free are 9.375" x 24" x 48", but they're easy to glue together.

Luke is right, it doesn't take much of a skin to make something quite strong. EPS with a spar in the middle, wrapped in strategically oriented packing tape, may even be P1-speed tolerant.

Hey Luke. If you'll make your car look like this, I'll deliver all the foam it requires. ;)

I also raced RC cars competitively and those were the only connectors (beyond directly soldered wires) that held up to the 100+ amps we'd put through them.

You two are welcome to any of my state-of-the-art-for-1995 RC racing stuff. I have a couple of 540-sized motors that consumed about 800W @ 7V (for 5 minutes at a time). Although... Seth may get tired of doing a full motor rebuild for every 5 minutes of run time.

About the foam, the biggest thing I can get is 4ft x 24ft by 38in. The biggest blocks I can get for free are 9.375" x 24" x 48", but they're easy to glue together.

Luke is right, it doesn't take much of a skin to make something quite strong. EPS with a spar in the middle, wrapped in strategically oriented packing tape, may even be P1-speed tolerant.

Hey Luke. If you'll make your car look like this, I'll deliver all the foam it requires. ;)

"Christina", New #13/#55x, '90 Miata: In progress

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

"Keiko", Old #13x/#55x, '96 Miata: R.I.P.

Daily Driver: '11 Mazda2 (small cars... some men have nothing to compensate for)

Re: Evolution of a young hillclimber.

I'm hoping to directly solder to the battery and replace the f terminal connectors. However, I didn't want to make that jump just yet until I was happy that I wired everything correctly and had a better idea of wire routing etc.

I'm really at a conundrum relative to the "push to pass" turbo button. They say these things really can't handle 24v power, mostly in the gearing department. I've thought about putting RC motors in places.

I really don't want to deal with separate 6v batteries and a 6v charger, to have an 18v setup.

The lazy part in me says I should just use the half dead 12v 7ah old batteries as the turbo setup. Figuring that it won't offer full juice, and if I use a temporary button Andrew has to hold down, he won't use it as much. I guess the big problem is going from stop to go, is a big shock on the drive line.

Toying with the idea of adding something like lights or something that come on with the turbo button to help pull some available power away, but I'm not sure that is sound logic.

Paul, since you were an RC guy.....the last time I ran them was late 80's early 90's. I seem to remember cleaning the motors with some "special" fluid and also remember a company paragon that had some sort of dropper bottle that would constantly drip fluid on the brushes of the motor to up performance for a few. Have any idea what that stuff was?

Still trying to figure out the wing thing too.

Below is diagram of the schematic of the push to pass setup, that someone else posted online.

I have this harness all built with the exception of a switch, I really want to use a temporary switch, so he can't just leave it at full power all the time. I have a really cool switch with coiled wire that is intended to velcro on to a steering wheel, but I'm afraid it can't handle the load.

I'm really at a conundrum relative to the "push to pass" turbo button. They say these things really can't handle 24v power, mostly in the gearing department. I've thought about putting RC motors in places.

I really don't want to deal with separate 6v batteries and a 6v charger, to have an 18v setup.

The lazy part in me says I should just use the half dead 12v 7ah old batteries as the turbo setup. Figuring that it won't offer full juice, and if I use a temporary button Andrew has to hold down, he won't use it as much. I guess the big problem is going from stop to go, is a big shock on the drive line.

Toying with the idea of adding something like lights or something that come on with the turbo button to help pull some available power away, but I'm not sure that is sound logic.

Paul, since you were an RC guy.....the last time I ran them was late 80's early 90's. I seem to remember cleaning the motors with some "special" fluid and also remember a company paragon that had some sort of dropper bottle that would constantly drip fluid on the brushes of the motor to up performance for a few. Have any idea what that stuff was?

Still trying to figure out the wing thing too.

Below is diagram of the schematic of the push to pass setup, that someone else posted online.

I have this harness all built with the exception of a switch, I really want to use a temporary switch, so he can't just leave it at full power all the time. I have a really cool switch with coiled wire that is intended to velcro on to a steering wheel, but I'm afraid it can't handle the load.

Sachilles

02 Subaru impreza (Donut) #66

02 Subaru impreza (Donut) #66

Re: Evolution of a young hillclimber.

It figures that RC racing is just like any other form of racing with a motor. Push it right up to the edge breakdown.Chief Geek wrote:Although... Seth may get tired of doing a full motor rebuild for every 5 minutes of run time.

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Evolution of a young hillclimber.

For the PTP go with the 30-40 amp Bosch style relay and control it with whatever low current momentary switch you like. The relays are cheap, switches that can handle the sort of current motors draw are not. There are also solid state solutions, but for this project that is probably more complex than appropriate and only useful if you find yourself burning up relays.

If the old 12v doesnt work out for PTP power, you can just get 2 6v and alternate between them, charging them in series with a 12v charger when they both need it.

Sent from my SCH-I545 using Tapatalk 2

If the old 12v doesnt work out for PTP power, you can just get 2 6v and alternate between them, charging them in series with a 12v charger when they both need it.

Sent from my SCH-I545 using Tapatalk 2

The older I get the better I was.