I got a little side-tracked today, and worked on a slightly different project. I really hate having to maintain 'excess' features without good reason, so I've been working on a side project to clean this up quite a bit, while opening some new aftermarket upgrade options to myself. Let's discuss in phases.

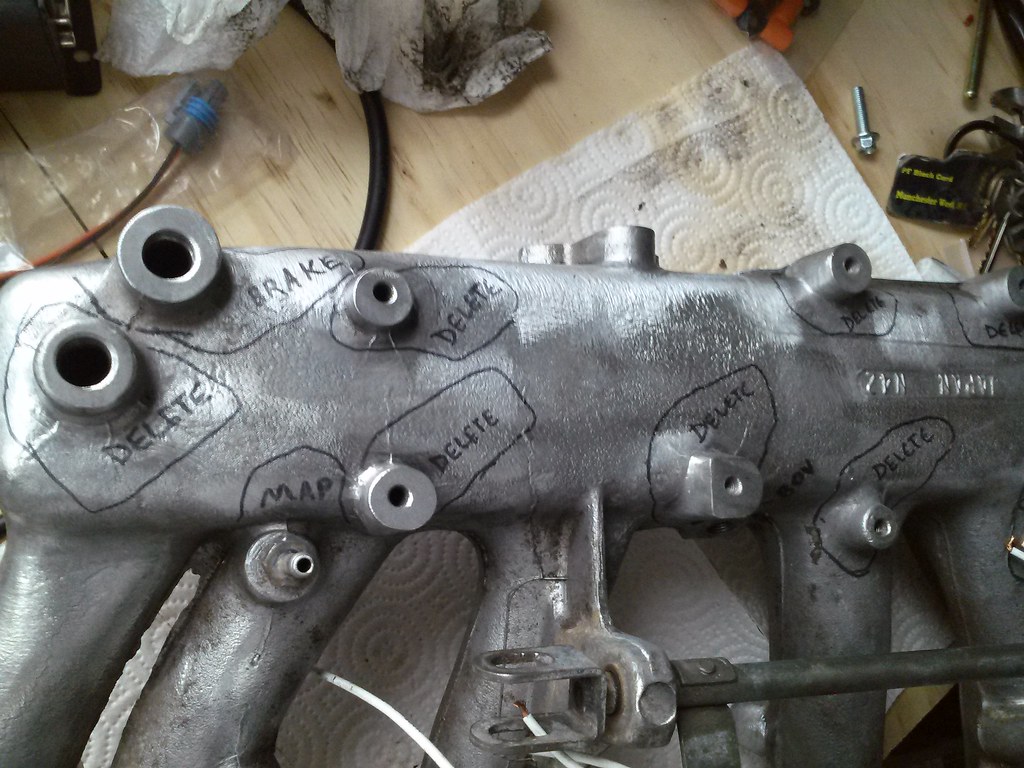

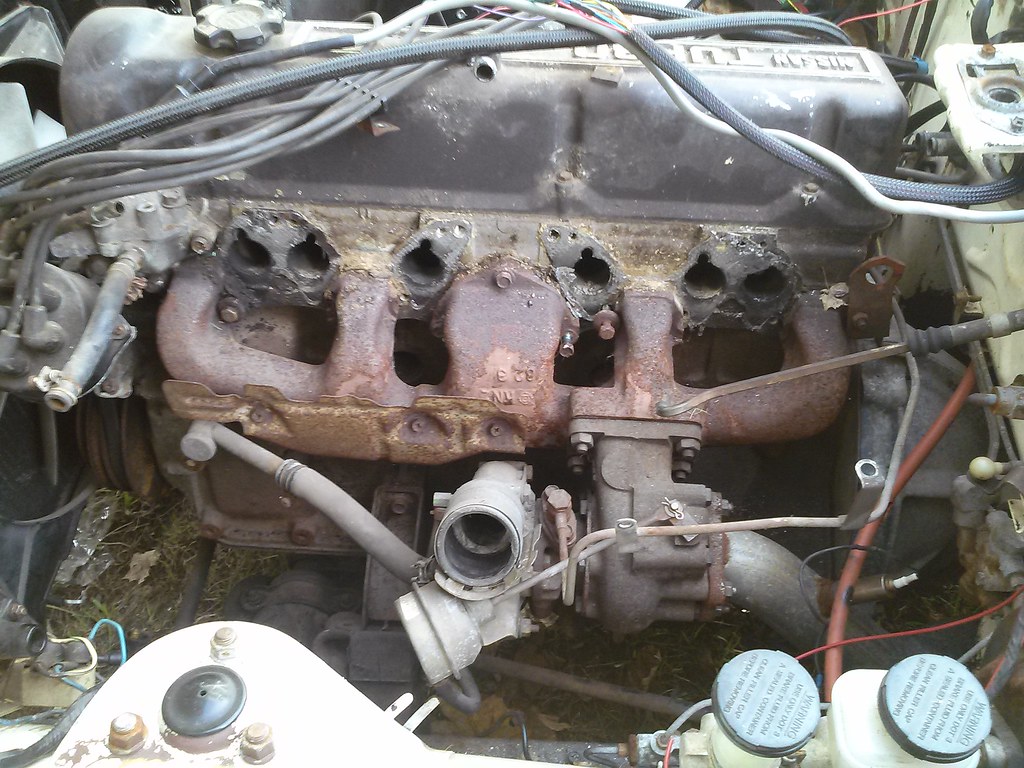

As you may have already noticed, the l28et intake manifold and associated vacuum routing leaves a lot to be desired.

Manifold Design

Manifold Design

Nissan experimented with casting in 'webbing' between the intake runners, to try to keep the exhaust heat (this is a non-crossflow engine, so remember that the turbo and exhaust are DIRECTLY under the intake manifold) from circulating into the head too much. That caused access issues, and even when cleaned up as much as possible, was a pretty ugly thing:

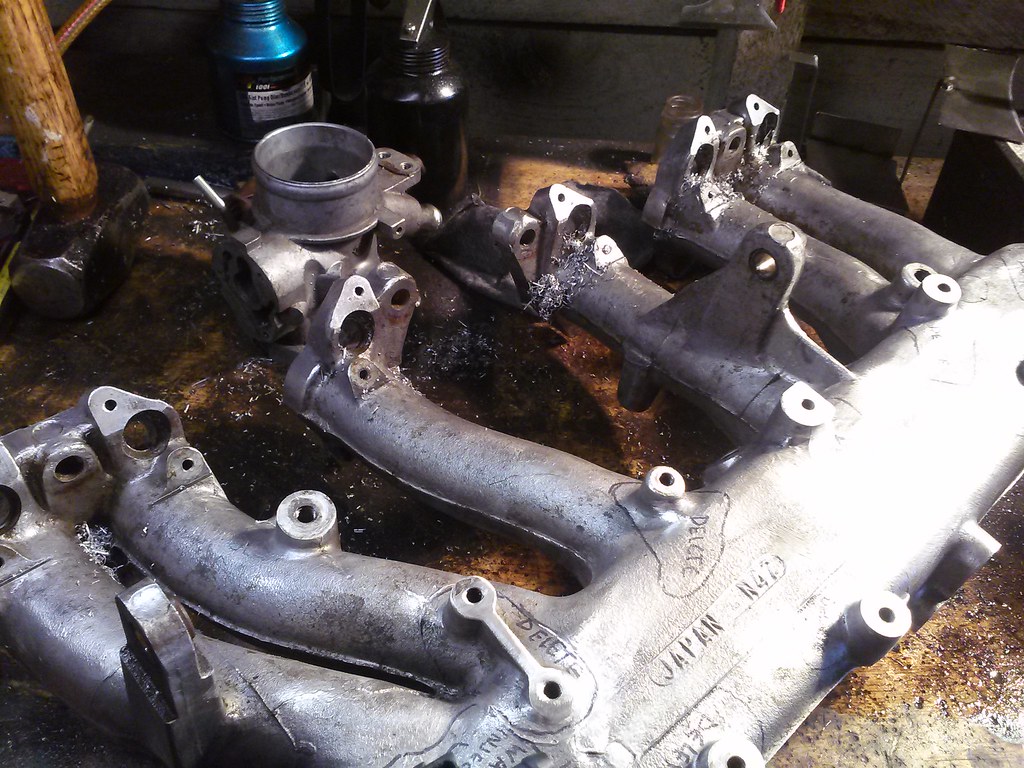

The intake manifold that came with the car (not the engine, which came from a 280zx-t) isn't exactly a work of art either, but can be cleaned up and simplified. I happened to have the original lying around, and decided to tear it down and prep it for replacement:

Fuel Delivery

Fuel Delivery

The fuel rail is a convoluted tube of steel (you may recognize it as brake lines from normal cars), and the injectors are connected to this tube of steel via some rubber hoses. The injectors themselves are single-squirter designs, and flowed roughly 270cc/min @ ~42psi. As you might imagine, these hoses are in GREAT shape after 40+ years of neglect.

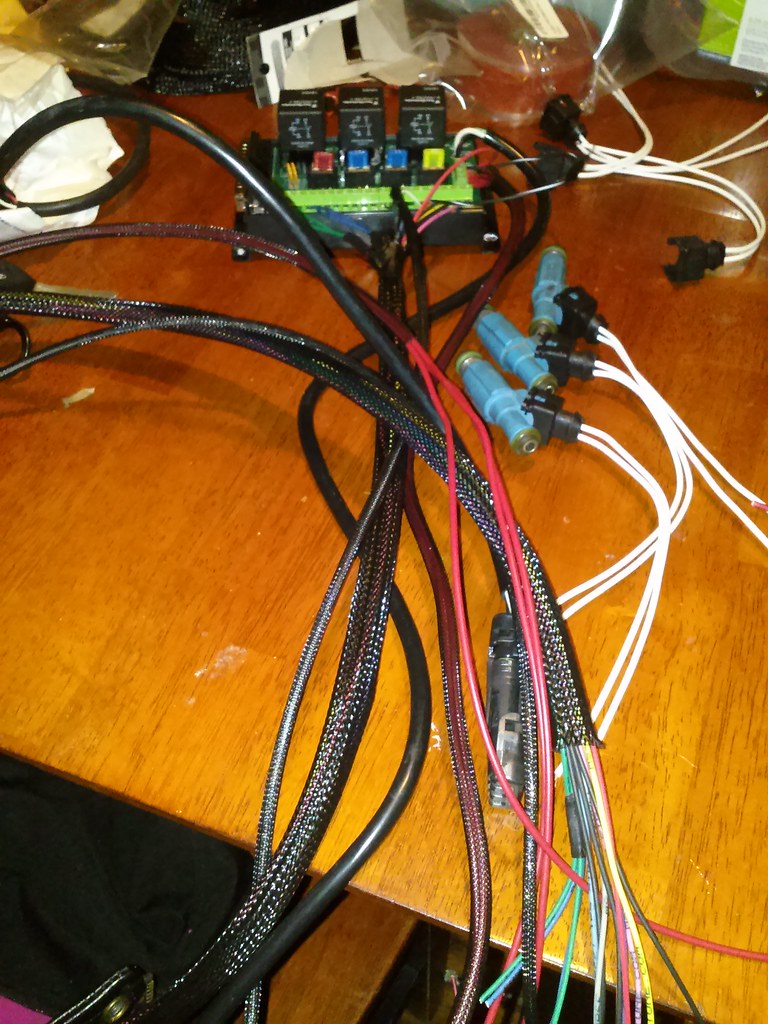

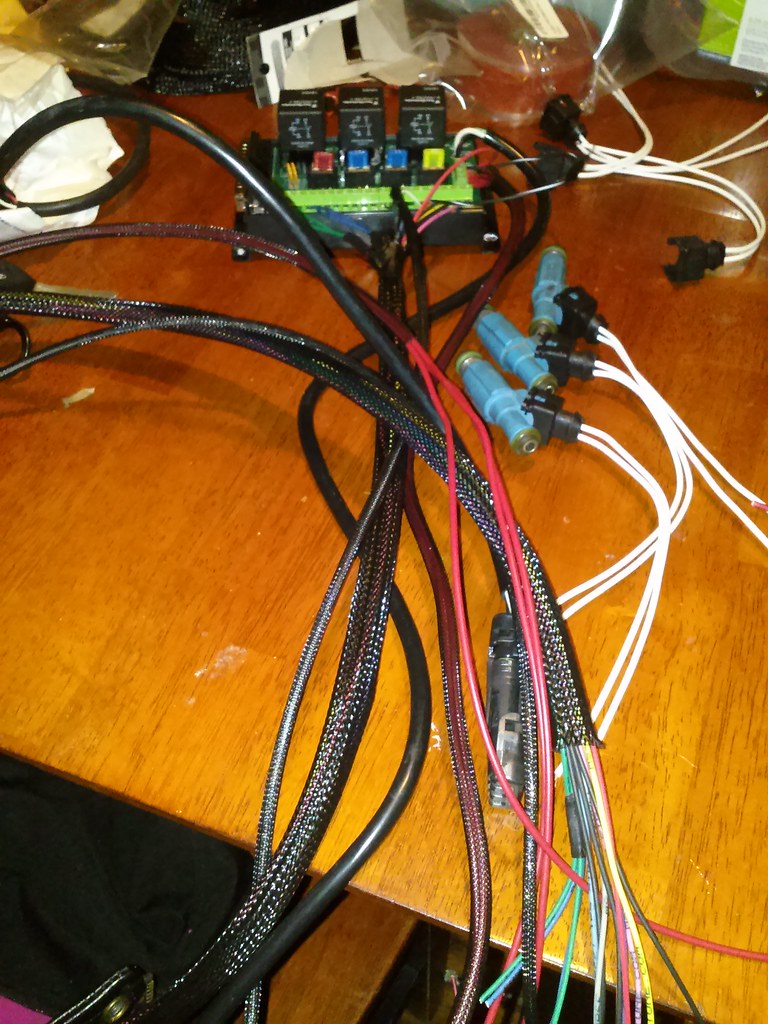

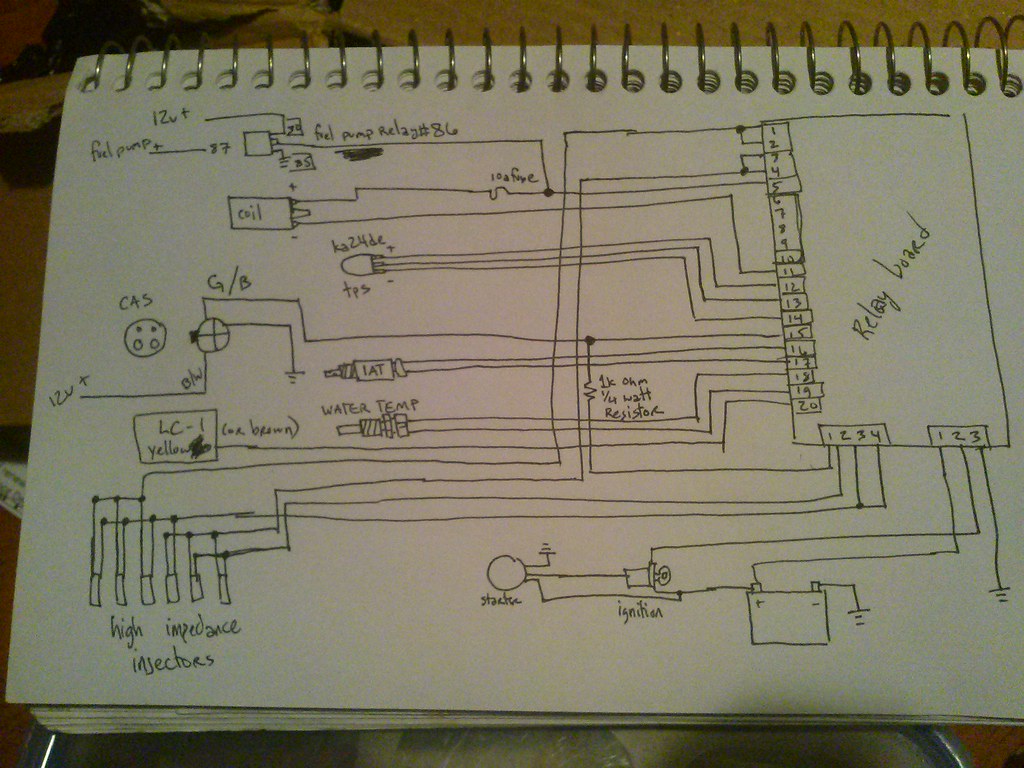

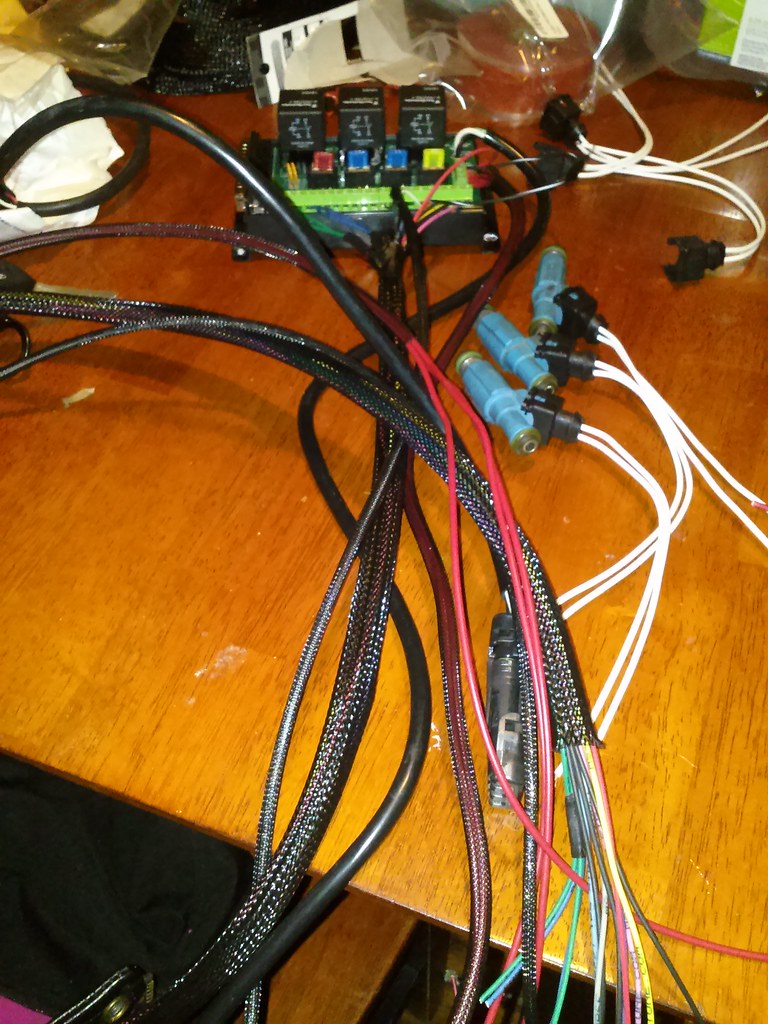

While I'm not looking to make astronomical amounts of power (200whp shouldn't be asking too much out of a turbo 2.8liter), I would like better reliability and parts availability should something go wrong. I was lucky enough to have a friend give me some Ford Cobra EV1 24# injectors (~252cc/min, slightly less flow than brand-new Nissan injectors), and because they're so standardized and prevalent, and a 'better' 4-hole design, I thought I'd try to standardize my equipment to be able to use them. Luckily, they use the same electrical connectors, so if they don't work for some reason, I can switch back easily. The main selling point for these injectors is the ease of upgrade/replacement (~$125 for ~35# injectors, and the 24# injectors should suit my needs for this season without going over 70% duty cycle), but also the fact that they're high impedance. High impedance is a lot less of a pain than low impedance (stock Nissan), and can be wired in to Megasquirt with no modifications. I like no-modification installations, especially in regards to anything electrical.

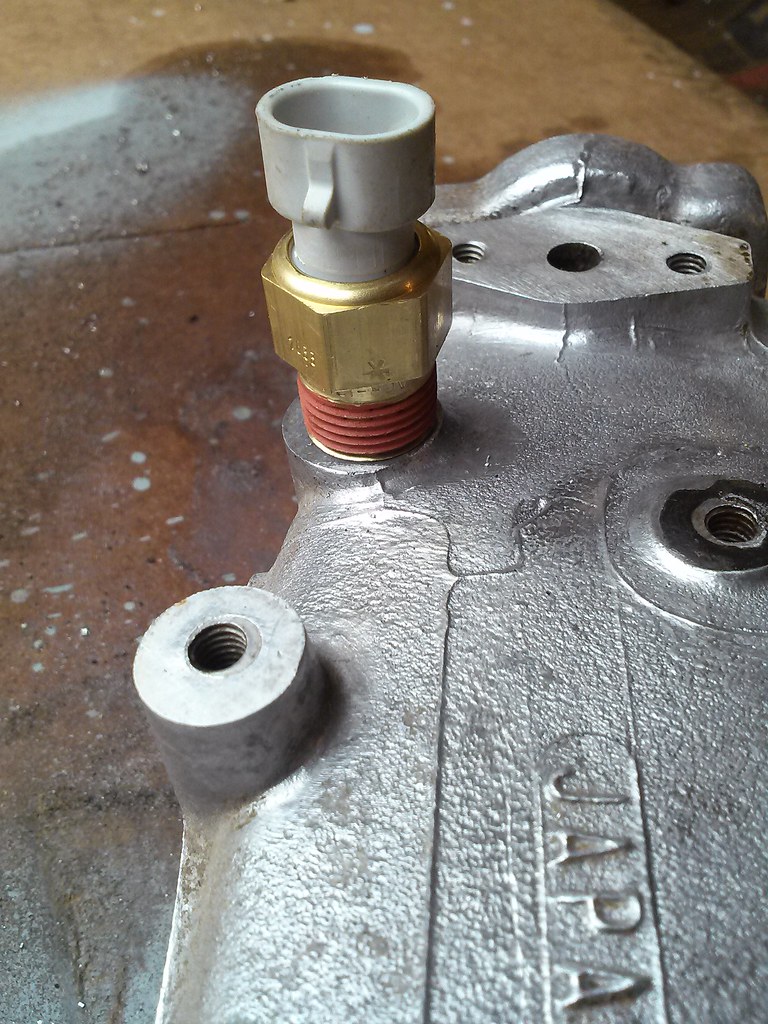

These injectors have 14mm orings on the fuel rail side and 14mm orings on the manifold side. I did some hunting, and found a Datsun-specific manufacturer who happens to make 14mm fuel rails for the l-series engines (Pallnet, for those who might be wondering). I contacted him, and received my fuel rail this morning. Excitedly, I mocked everything up to see how it fits, and was excited that I only found one issue with the fitment, on my cleaned-up stock intake manifold:

The injectors fit the fuel rail perfectly, the fuel rail fits the manifold beautifully, but the injectors don't fit the manifold bungs. They sit on top of the bung, in fact. That won't seal at all, and I've been told that spraying fuel all over the inside of an engine bay is a bad thing (who knew?!)

So coming up sometime this week (hopefully) I'll be able to drop the manifold off with my friend and have her machine the bungs a bit so the injectors can actually seat in the manifold, rather than on it. More updates to come when I have a bit more progress made, but it looks like I'm going to be adding vacuum lines and mounting this in the engine bay in pretty short order.