Time for a little work on the electrical system.

First up are some battery updates. We had been using some 12v sla type batteries, and they were 7.4 ah. Well they worked pretty well, but due to mistakes on my part storing the batteries over the winter, they seemed to have diminished capacity this summer in terms of endurance. We were lucky to get 5-10 minutes out of one, and their strength didn't quite seem up to task.

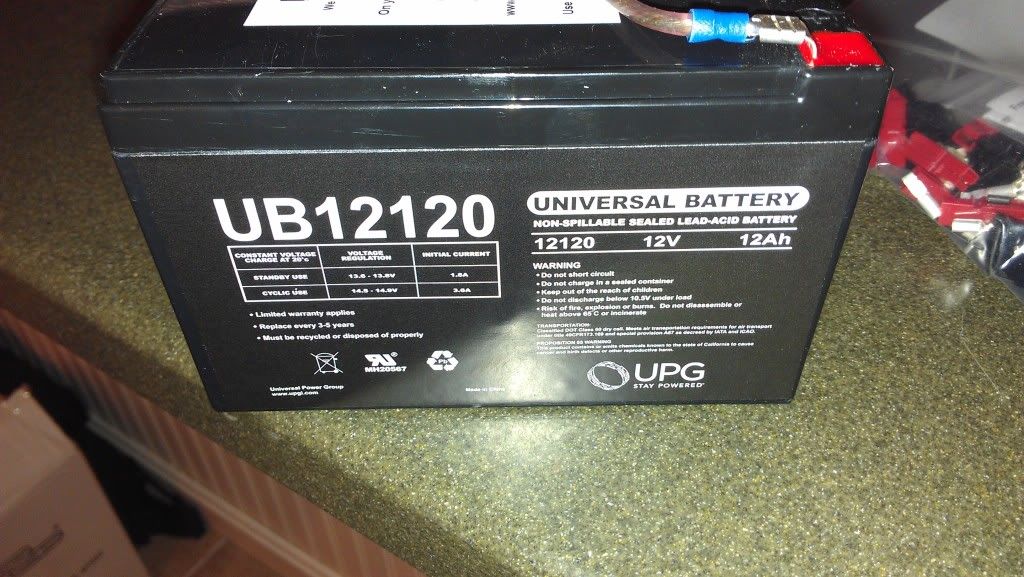

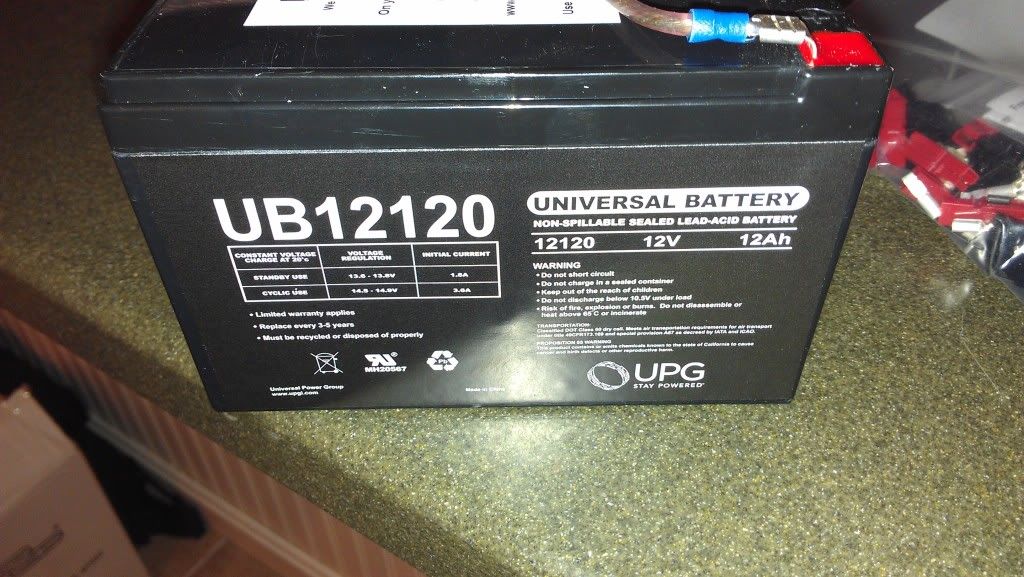

So ebay came to the rescue, and we bought 4 of these bad boys for about $80 shipped on ebay.

These are 12ah. First time out we got 30 minutes out of one, and parked it with plenty of good life left. We really don't want to kill the battery under load if we can avoid that.

Issue number 2 was improving power connections and replacing some rather thin wire. I had been using generic grote two pole connectors. My battery charger used them, and the local parts store sold pairs of the connectors pre-wired for cheap enough...so I had went with them. Well, the connectors and wiring just were not up to the task, causing the connectors to get hot, and start to get soft. Eventually, they'd connect even more poorly and get worse by the use.

I figured that better batteries would be wasted with the old connections. So I searched the internet for some better connectors, and came across the power pole connectors. I had used them when I was a kid on my radio control race cars and thought they were awesome then. I figured the 45 amp connectors would do the trick and ordered up a bunch. I also replaced the thin gauge wire with much thicker gauge wire scrounge up from some "monster cables".

I shortened wires where I could and eliminated crimps where practical, soldering what I could. I'm happy to report after our 30 minute lapping session, that there were no warm wires or any other wiring issues.

Now 30 minutes is a long time to wait around while you watch your son having all the fun driving the gator around the "track". I won't say it got boring, but it wasn't the most stimulating experience....so my mind began to wander a little.....then I realized I had my phone with me, and it has datalogging capability. By this time we were 25 minutes in to the session and I perceived that the battery could be weakening a little bit. However it was still better than the old ones. So I had Andrew come in for a pit stop and I installed the datalogger, and sent him on his way. I'm pleased to report that he was able to manage a peak of 11.74 mph in a gravity and wind aided sprint. On flat ground he was averaging 6 mph or so and about 3 mph on the uphill sections of our yard. He posted a maximum reading of 0.46 g on acceleration, given the grip of plastic tires its quite impressive. This is all on 12 volts.

This was some good progress I think. I may have to investigate the motors a little bit, sure look like the old motors I used in radio control cars back in the day. I'm betting I might be able to swap something a little faster than stock. They appear to have the same mounting setup. Of course I can up the voltage as well. Still trying to figure out the best way to skin the cat in that regards. It has a twin motor setup(one for each wheel). I'm thinking I may want to individually power each wheel.

So we now face the age old dilemma of getting a little more power hungry, knowing full well that more power means less reliability. What to do, what to do?