Yeah fenders are overrated!sdwarf36 wrote:Let'em hang out in the wind.

Happy Birthday to me (280z build)

Re: Happy Birthday to me (280z build)

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

Not quite yet. I'll need to bring the wheels up for Joey first, and the rear hubs still need to be converted to 5-lug (parts are delivered, but they need a dose of time). I don't think Joey's going to weld the front subframe pickups in until the engine is in (more on this later).dsldubn wrote:Autocross is flat with no hills, not quite apples to apples comparison to hillclimb. Either way, I just was curious as it seems like a lot of work for the flares and I was thinking you were under pressure to get it done for this season start. I like wide tires and flairs too, all good, and I'm sure it'll look awesome. Too bad there wasn't a flare already out there that might work and ease the amount of fab. I wouldnt' be surprised if bushwacker, who makes offroad flares, might have something that would fit. They make some really nice flexible ones that may fit the bill and would be real wide since they are meant for covering extreme poke from offroad rigs. Also there's a bunch of ebay stuff that could work. these are big enough, but you get the idea. maybe something like that to reduce the list 'o stuff to build http://www.ebay.com/itm/like/2719934519 ... noapp=true

I'm looking forward to seeing this car together. Is it a roller yet?

Autocross is the closest approximation I can come up with. Very few other motorsports have such short runs, so autocross is the best place for me to benchmark tires from. I don't really know what the car's going to need.

As for the overfenders, the BAMF ZG overfenders are 6" wider in the rear and 3.5" wider in the front. They're the widest I've found, but they aren't quite wide enough and are still pretty expensive. I could do some wobbly-rubber-garden-edging overfenders, but nice fenders is the 'luxury feature' I'd like to see the most. I've always liked working with composites, and these are already starting to look cool, in my mind. There's only so much I can do from home 'till I have the car back down here, and this is one of those projects.

Have to be able to drive it to work. The last time I checked, NH requires fenders that cover all but 1" of your tire. Otherwise, I like the simplicity of open-wheel.KevinGale wrote:Yeah fenders are overrated!sdwarf36 wrote:Let'em hang out in the wind.

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Happy Birthday to me (280z build)

Besides, integrated fender flares make everything look AWESOME!

From what I have seen, those universal JC Whitney, errr...JDM, bolt-on flares dont really fit any car correctly and when screwed in place to follow a cars fender shape you end up with an odd shaped lip opening.

From what I have seen, those universal JC Whitney, errr...JDM, bolt-on flares dont really fit any car correctly and when screwed in place to follow a cars fender shape you end up with an odd shaped lip opening.

The older I get the better I was.

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

There are well-fitting bolt-on flares for the s30 chassis. Because bolt-on flares were a factory feature on the Fairlady, this chassis style really received a lot of attention-to-detail. Cars just keep getting bigger, and using modern parts on a small chassis means everything is super-sized.walterclark wrote:Besides, integrated fender flares make everything look AWESOME!

From what I have seen, those universal JC Whitney, errr...JDM, bolt-on flares dont really fit any car correctly and when screwed in place to follow a cars fender shape you end up with an odd shaped lip opening.

Update

Just after assembling my Megasquirt configuration and drawing out the engine harness for it, a new development meant that I don't need it any more. The plan was to use the $1200-craigslist-engine-and-transmission with MS3X, toss the ct26 mr2 turbo on it, make some intake/exhaust ductwork, and tune it as quickly as possible. I had compression tested the Craigslist engine, but that's not a definite thumbs-up on rotaries. Leakdown testing isn't really a thing with rotaries, so without tearing it down and putting it back together, it's mostly just hoping everything works. That's too much for me.

I lucked out and ended up with a pre-tuned pre-assembled engine that just barely squeaks in under my budget (the budget needed to get a little stretchy for it). It's essentially what I would like to build for CTTC in 2017, with the main advantage being that it's ready to run now. It's already been shaken down, broken in, and tuned.

Somehow, the word "excited" doesn't begin to cover it. At this point, I have three 4port rotary engines, and I think I'm finally standardized. Time to sell off the Miata spares and 302's.

Re: Happy Birthday to me (280z build)

That must be why I work from home.drummingpariah wrote: Have to be able to drive it to work. The last time I checked, NH requires fenders that cover all but 1" of your tire. Otherwise, I like the simplicity of open-wheel.

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

It looks like my math was a bit off, since 'stock wheel size' is far from 'max wheel size with stock fenders' ... it looks like 10" wheels/tires just BARELY fit under the stock suspension with stock fenders. That means I can chop off around 5" from my flares on each side. Much more manageable.

In other news, I now have two rotary engines sitting in the garage, and one sitting at Joey's shop. Something something rotary triangle something three is the right number?

I also tore down my tail light housings. I think I'm going to end up towing the car for Ascutney 1 (that's more work than I have time for), but after that I want to get it street-legal as quickly as possible. I like the idea of being as visible as possible across the board, and the ancient incandescent bulbs really don't cut it. I'm already rewiring the car, so I'm exploring different options to get the best lighting possible.

I've never liked the 'OEM replacement LED bulbs' that are shaped like incandescent bulbs but with little LED growths on the sides. They're compromised in a lot of ways, and I already have a bunch of 12v LED strips that I could use. They seem to fit pretty nicely, so I'm going to do some testing to see how they look wired up.

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

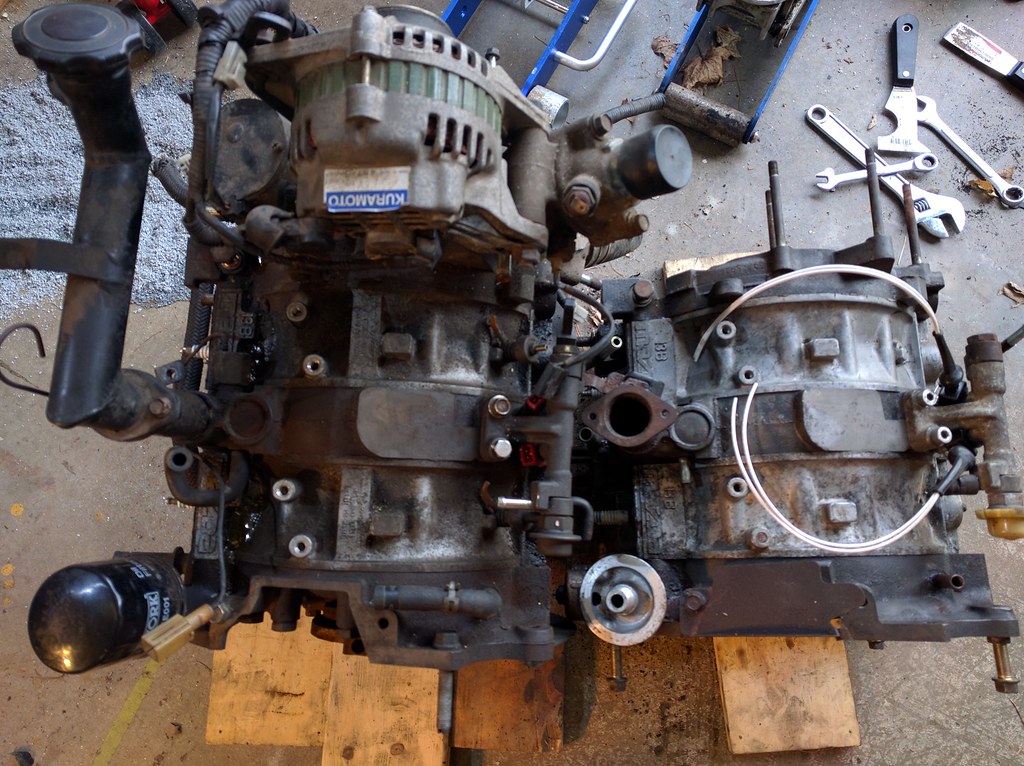

No real update, but I can drop this off as a reference of scale. The engine will probably end up slightly farther forward than this, but I think it can safely be called 'mid engine'

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

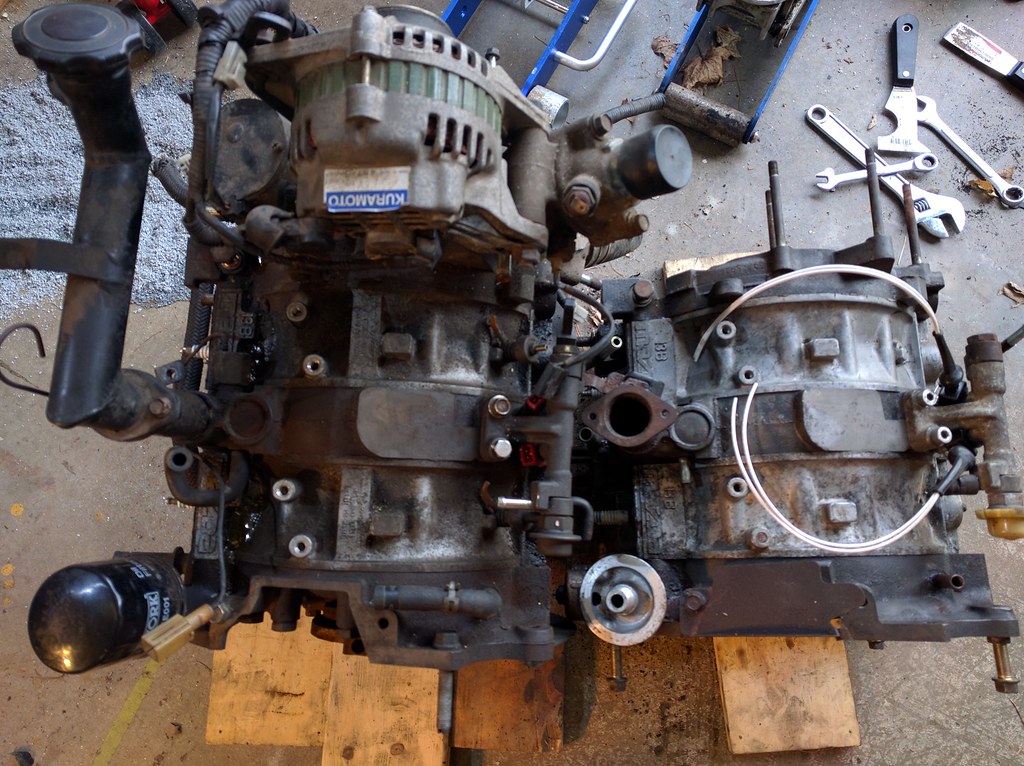

Because the new engine is going in, I now have the 'leftovers' of stuff that isn't going into the car in my shop. That means cleaning, organizing, and storing needs to happen (before the car shows up). This is unacceptable:

I started by shuffling some parts around, and making room in the 'engine room'. Because I know I won't using OEM EFI on this car, I decided to tear all the extras off of the assembled-spare 13b.

I started with this and a beer:

And ended with less clutter, and no beer. Here's the mockup housing assembly next to the 'assembled spare' block.

The turbo goes on the 'spare turbos' shelf. If there's any kind of market for it, I'll happily sell the harness/ecu/manifold/turbo/lines off to whoever is interested enough to make it worth putting them in a box. I have no idea what it takes to convert n/a to turbo, or if any of this is worth anything.

One interesting discovery I came up with is that these two engines apparently have different rotor housings. Otherwise, they appear to be identical.

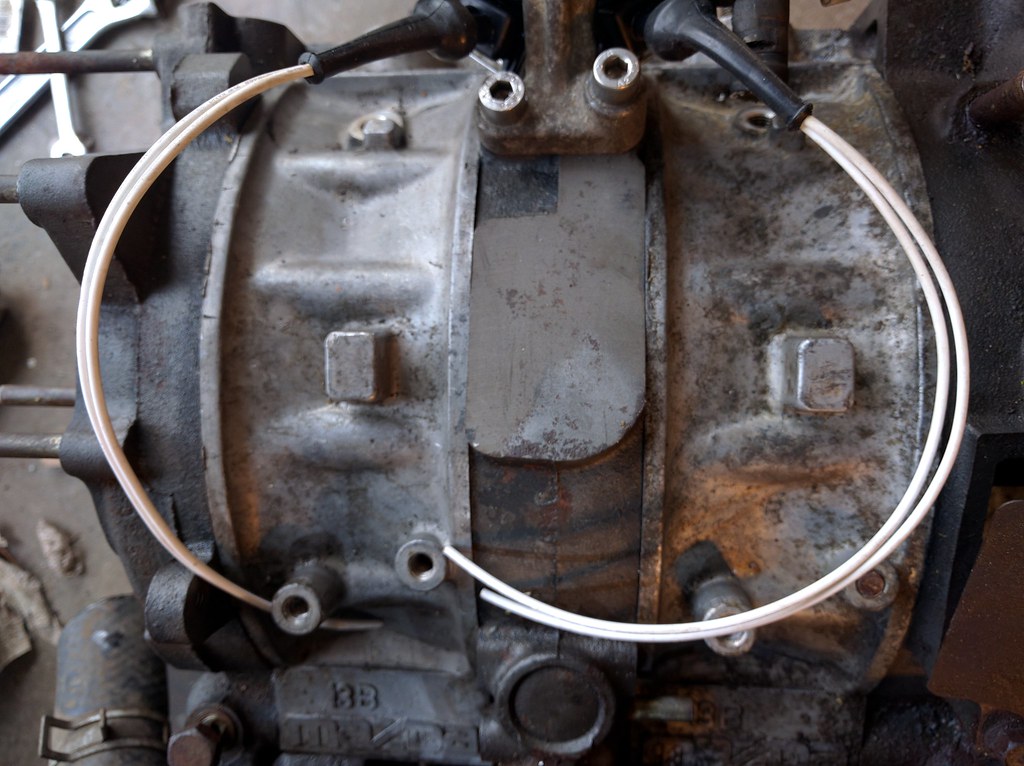

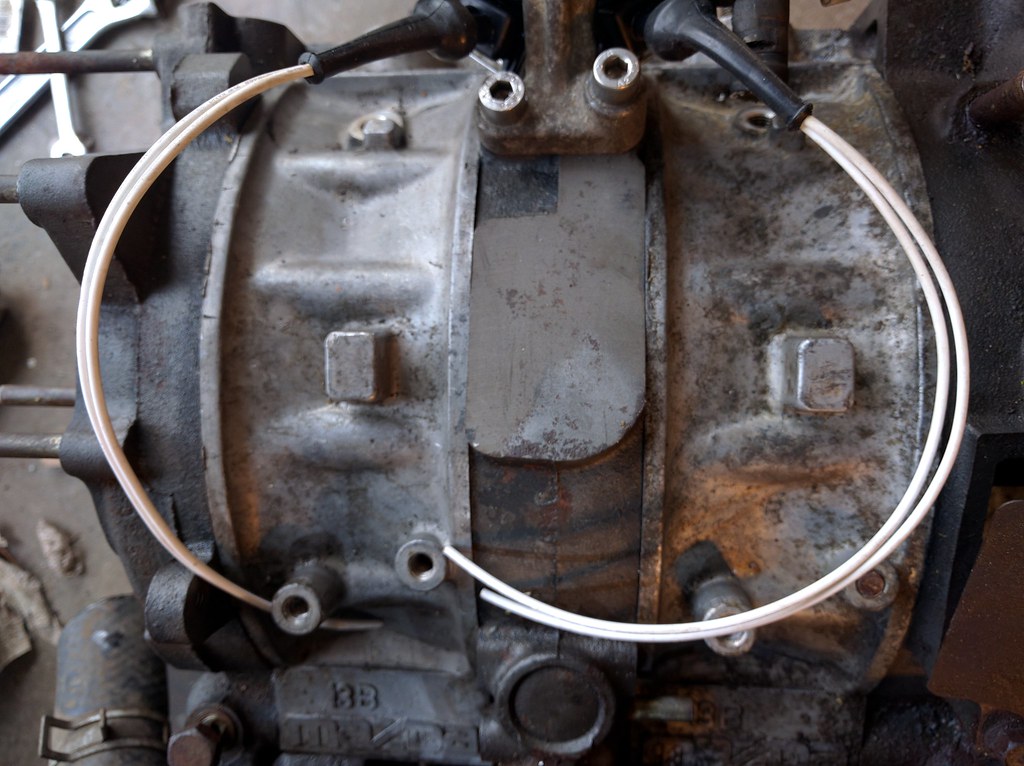

One with no markings on top

The other with licensing markings on top.

As for accessories, here's one of the spare transmissions (I now have three turbo2 transmissions), and two of the intake manifolds (again, I have a total of three right now).

That emissions block-off kit is really disappointing. It's so thin that I can't use the stock studs. I can either draw up a DXF (just put these on a flat-bed scanner and scan them 1:1) and have Big Blue Saw cut out some proper plates, or pull those studs and use bolts instead. Generally speaking, I find that steel studs in aluminum don't come out as easily as I'd like. I'm leaning toward slightly girthier blockoff plates.

I started by shuffling some parts around, and making room in the 'engine room'. Because I know I won't using OEM EFI on this car, I decided to tear all the extras off of the assembled-spare 13b.

I started with this and a beer:

And ended with less clutter, and no beer. Here's the mockup housing assembly next to the 'assembled spare' block.

The turbo goes on the 'spare turbos' shelf. If there's any kind of market for it, I'll happily sell the harness/ecu/manifold/turbo/lines off to whoever is interested enough to make it worth putting them in a box. I have no idea what it takes to convert n/a to turbo, or if any of this is worth anything.

One interesting discovery I came up with is that these two engines apparently have different rotor housings. Otherwise, they appear to be identical.

One with no markings on top

The other with licensing markings on top.

As for accessories, here's one of the spare transmissions (I now have three turbo2 transmissions), and two of the intake manifolds (again, I have a total of three right now).

That emissions block-off kit is really disappointing. It's so thin that I can't use the stock studs. I can either draw up a DXF (just put these on a flat-bed scanner and scan them 1:1) and have Big Blue Saw cut out some proper plates, or pull those studs and use bolts instead. Generally speaking, I find that steel studs in aluminum don't come out as easily as I'd like. I'm leaning toward slightly girthier blockoff plates.

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Happy Birthday to me (280z build)

The older I get the better I was.

- drummingpariah

- Posts: 498

- Joined: Wed Mar 20, 2013 7:13 pm

- AntiSpam: No

- Location: Manchester, NH

- Contact:

Re: Happy Birthday to me (280z build)

Could certainly work, but I'm definitely not opposed to having a little more rigidity on my sealing surfaces. Vacuum leaks are no fun.

Most of tonight was spent simply cleaning/organizing. I still don't have a clean floor, but I did get to dig the dashboard out of the basement and start prepping it for molding.

For those who don't know, s30 dashboards were made of vinyl-wrapped foam that was susceptible to cracking if exposed to sunlight for more than a few years. It's pretty close to impossible to find an original, un-cracked dash these days, and most people just toss a plastic cap on top and call it good. Generally speaking, that works great. It looks good, and the dashboard doesn't need to be structurally sound.

However, the stock dash is pretty heavy. I really can't justify trying to use those old original gauges either, especially with a standalone ECU where I can drive any gauges I want. I do love the design of the s30 dash though, so I decided to repair the surface and pull a mold from it. Fiberglass should work just fine for this.

The first step is to fill the large voids left by the cracks. I used some 2lb expanding urethane foam, because it's so easy to work, is fairly rigid, and is stronger than body filler when filling large gaps. I think it took around 15 minutes to go from a badly cracked dash to a mostly-smooth one.

https://www.youtube.com/watch?v=KYwzVIUsNMA

A quick rasping, and I had this

After that, I mixed up some fiberglass reinforced body filler and because it's chilly out, decided to call it a night. I'll get to sanding it down and finishing the surface after work tomorrow.

Most of tonight was spent simply cleaning/organizing. I still don't have a clean floor, but I did get to dig the dashboard out of the basement and start prepping it for molding.

For those who don't know, s30 dashboards were made of vinyl-wrapped foam that was susceptible to cracking if exposed to sunlight for more than a few years. It's pretty close to impossible to find an original, un-cracked dash these days, and most people just toss a plastic cap on top and call it good. Generally speaking, that works great. It looks good, and the dashboard doesn't need to be structurally sound.

However, the stock dash is pretty heavy. I really can't justify trying to use those old original gauges either, especially with a standalone ECU where I can drive any gauges I want. I do love the design of the s30 dash though, so I decided to repair the surface and pull a mold from it. Fiberglass should work just fine for this.

The first step is to fill the large voids left by the cracks. I used some 2lb expanding urethane foam, because it's so easy to work, is fairly rigid, and is stronger than body filler when filling large gaps. I think it took around 15 minutes to go from a badly cracked dash to a mostly-smooth one.

https://www.youtube.com/watch?v=KYwzVIUsNMA

A quick rasping, and I had this

After that, I mixed up some fiberglass reinforced body filler and because it's chilly out, decided to call it a night. I'll get to sanding it down and finishing the surface after work tomorrow.