The tenzo's are pretty much Sparco knock offs. We carry their wheel line. I am not sure if they even make the seats anymore.

I just read this really quick so I am not sure if anyone mentioned it but I have found the fastest easiest way to remove Sound deadening is to use dry ice. Just put it on a spot for about 30 seconds give it a wake with a chisel and it will just break apart. I used this method in the nissan and it made for pretty quick work.

Project Rookie

-

W.Vaillancourt

- Posts: 130

- Joined: Mon Feb 09, 2009 2:04 pm

Re: Project Rookie

Well that's good to know that the ice works. I'm still going to give myself a couple weekends to gut it all out.

Seth: Yes, putting in a 4 point roll bar would be the ideal situation. However, I would like to save that step for when it is absolutely necessary, to save costs for the time being, I'm hoping to spend more of the budget on entry fees rather than the car. Seat time with autocrossing, track days, and more hillclimbs will help more than adding a racing seat I think.

That being said, while searching online today, Benen Industries makes this 'B-pillar bar" for my car that bolts to the seat belt mounts behind the front seats.

According to the website, the bar is made of steel tubing (doesn't specify which kind though) that is 33mm (~1.29") in diameter, with a wall thickness of 0.120". The endplates are 3.6mm thick.

Walter had said that it would be ideal for the bar to be about bottom-of-the-window height. This B-pillar bar is higher than that as you can see, but if I mount a brace like this one

underneath the bar, rather than above it (still bolted to the seat of course), is it still too high? It would bolt to the seat just below the shoulder harness pass-throughs.

This question is simply thinking out loud in case I ever need to make a brace. I drew up a DIY version of the one pictured above while at work today (gotta stay busy you know!). It places the brace about 2" below the level of the bar in the first photo. I just didn't know if mounting higher up on the seat-back as opposed to lower is still considered legal/safe (it seems like it would still perform the same function).

Thanks for feeding my engineering curiosity.

-Lincoln

Seth: Yes, putting in a 4 point roll bar would be the ideal situation. However, I would like to save that step for when it is absolutely necessary, to save costs for the time being, I'm hoping to spend more of the budget on entry fees rather than the car. Seat time with autocrossing, track days, and more hillclimbs will help more than adding a racing seat I think.

That being said, while searching online today, Benen Industries makes this 'B-pillar bar" for my car that bolts to the seat belt mounts behind the front seats.

According to the website, the bar is made of steel tubing (doesn't specify which kind though) that is 33mm (~1.29") in diameter, with a wall thickness of 0.120". The endplates are 3.6mm thick.

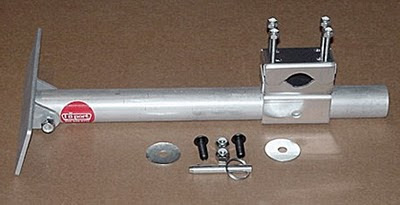

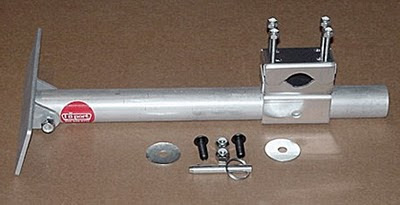

Walter had said that it would be ideal for the bar to be about bottom-of-the-window height. This B-pillar bar is higher than that as you can see, but if I mount a brace like this one

underneath the bar, rather than above it (still bolted to the seat of course), is it still too high? It would bolt to the seat just below the shoulder harness pass-throughs.

This question is simply thinking out loud in case I ever need to make a brace. I drew up a DIY version of the one pictured above while at work today (gotta stay busy you know!). It places the brace about 2" below the level of the bar in the first photo. I just didn't know if mounting higher up on the seat-back as opposed to lower is still considered legal/safe (it seems like it would still perform the same function).

Thanks for feeding my engineering curiosity.

-Lincoln

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Project Rookie

Perhaps someone with extensive Kirkey experience can jump in here. Since Kirkey doesnt seem to support the notion of a back brace despite nearly all racing rules to the contrary, they appear to be of no help.

My take is the brace should be located somewhere between your shoulder blades. This is about the center of your upper body mass so the least likely place to mount the brace and have the seat back fold over or under the brace in a hard rear-end-first collision. You would want to have as large a plate as possible between the brace itself and the seat back to spread out an impact and reduce the likelihood of the seat back folding around it or the brace pushing thru.

My take is the brace should be located somewhere between your shoulder blades. This is about the center of your upper body mass so the least likely place to mount the brace and have the seat back fold over or under the brace in a hard rear-end-first collision. You would want to have as large a plate as possible between the brace itself and the seat back to spread out an impact and reduce the likelihood of the seat back folding around it or the brace pushing thru.

The older I get the better I was.

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Project Rookie

Here is a pic of one mounted in what looks like a fairly reasonable manner:

Note that this one is attached to a harness bar that is part of a cage. I am not a big fan of the bolt-in harness bars but what you describe seems almost reasonable. The real problem I see is the design intent of a harness bar and the loads from harnesses versus using it as the secure point for a back brace. Someone on our technical committee would need to provide a final word on the use of a bolt-in harness bar as part of the seat-back brace system.

The only problem I see here is the seat back will tend to fold down as well as back and that is the easy direction for the brace to move as well. It would be better if the harness bar to which it is attached were lower and the brace closer to level. Lower mounted harness bars used to be the norm when the recommended shoulder harness angle was 20-45 degrees down, but with the requirement from a lot of racing for head and neck restraints the required shoulder harness angle has been reduced (0-10 degrees) at the same time the straps sit higher on the wearer (raising the bars upwards of several inches).

Note that this one is attached to a harness bar that is part of a cage. I am not a big fan of the bolt-in harness bars but what you describe seems almost reasonable. The real problem I see is the design intent of a harness bar and the loads from harnesses versus using it as the secure point for a back brace. Someone on our technical committee would need to provide a final word on the use of a bolt-in harness bar as part of the seat-back brace system.

The only problem I see here is the seat back will tend to fold down as well as back and that is the easy direction for the brace to move as well. It would be better if the harness bar to which it is attached were lower and the brace closer to level. Lower mounted harness bars used to be the norm when the recommended shoulder harness angle was 20-45 degrees down, but with the requirement from a lot of racing for head and neck restraints the required shoulder harness angle has been reduced (0-10 degrees) at the same time the straps sit higher on the wearer (raising the bars upwards of several inches).

The older I get the better I was.

Re: Project Rookie

Thank you so much Walter (and everyone) for answering all these questions I've got. Much appreciated!

Re: Project Rookie

Kirkey's reccomendation:

http://www.kirkeyracing.com/index.php?l ... unting%20B

This is the bracket Kirkey reccomends for the seat (Intermeidate roadrace) - looks like this would bolt to a "harness" bar, as it bolts to the seat just below the shoulder harness ports. Kirkey does NOT reccomend use of stock seat rails. I would consider a simple fabricated floor mount ( square tube) instead of the Kirkey "flat floor" brackets.

Installation guide:http://www.kirkeyracing.com/related/Rel ... 0Guide.pdf

;

http://www.kirkeyracing.com/index.php?l ... unting%20B

This is the bracket Kirkey reccomends for the seat (Intermeidate roadrace) - looks like this would bolt to a "harness" bar, as it bolts to the seat just below the shoulder harness ports. Kirkey does NOT reccomend use of stock seat rails. I would consider a simple fabricated floor mount ( square tube) instead of the Kirkey "flat floor" brackets.

Installation guide:http://www.kirkeyracing.com/related/Rel ... 0Guide.pdf

;

John and Michelle Reed

KSCC Life Member

NEHA # 151

KSCC Life Member

NEHA # 151

Re: Project Rookie

Ok so this isn't part 3 of Project Rookie, but more of a plea for help. I have been working away on the little hatchback for the past few weeks a little at a time to remove the interior and strip as much out as I can. I had planned to go for a short test run today around the neighborhood, but no! The car won't start! I have tried every diagnosis I can think of, read about a hundred internet articles and forum discussions and I still cannot get it to start. The situation is as follows when I turn the key:

-no cranking at all

-fuel pump primes

-lights on the dash come on bright

-headlights and horn both work

-nothing changes when I try to jump it, same symptoms as when not jumping

I have replaced the battery with a brand new one and traced every ground that I can find. I unbolted each ground cable, cleaned off the bolt and bolt hole with a wire brish to get rid of as much corrosion as I can find, and replaced the ground connection. I pulled and checked all the fuses under the dash and under the hood, don't see any problems there either.

It seems like I have narrowed it down to the starter and/or power to the starter as the culprit. I don't have a multimeter at home to check for power in the cable to the starter. Is there a way to determine if my starter is bad, or if I just have a bad cable without a multimeter? (I have removed, cleaned and replaced that connection as well) Below is a picture I took of the starter in case someone can spot a connection that I am missing:

Also, here is a video of what happens when I turn the key. Again, the dash lights up and you can hear the fuel pump, but no cranking at all. I'm getting tired of the silence!

If anyone has any insight into what I might be missing or any ideas for a diagnosis/solution, I'm willing to try anything at this point. I want to run at Ascutney 2! Thanks a ton in advance for any replies.

-Lincoln

-no cranking at all

-fuel pump primes

-lights on the dash come on bright

-headlights and horn both work

-nothing changes when I try to jump it, same symptoms as when not jumping

I have replaced the battery with a brand new one and traced every ground that I can find. I unbolted each ground cable, cleaned off the bolt and bolt hole with a wire brish to get rid of as much corrosion as I can find, and replaced the ground connection. I pulled and checked all the fuses under the dash and under the hood, don't see any problems there either.

It seems like I have narrowed it down to the starter and/or power to the starter as the culprit. I don't have a multimeter at home to check for power in the cable to the starter. Is there a way to determine if my starter is bad, or if I just have a bad cable without a multimeter? (I have removed, cleaned and replaced that connection as well) Below is a picture I took of the starter in case someone can spot a connection that I am missing:

Also, here is a video of what happens when I turn the key. Again, the dash lights up and you can hear the fuel pump, but no cranking at all. I'm getting tired of the silence!

If anyone has any insight into what I might be missing or any ideas for a diagnosis/solution, I'm willing to try anything at this point. I want to run at Ascutney 2! Thanks a ton in advance for any replies.

-Lincoln

-

sciroccohp

- Posts: 243

- Joined: Mon Apr 21, 2008 6:49 pm

- Location: New Haven, CT

Re: Project Rookie

Carefully put a jumper cable from battery to starter main connection and try. If it cranks then cable if not then solenoid. (I vote starter solenoid myself)

- Rabbit Farmer

- Posts: 2260

- Joined: Wed Jun 25, 2003 11:37 pm

- AntiSpam: No

- Location: Earth

- Contact:

Re: Project Rookie

My vote also (or wires going to the solenoid)(I vote starter solenoid myself)

Go Fast VW & Audi parts at FastAddiction.com

Re: Project Rookie

Starters were very common in those. If you have no power to the solenoid (the small black wire with white tracer going to the starter) you could have a bad clutch interlock switch which is on the clutch pedal, unlikely but possible. To eliminate the interlock switch, unplug it,jump the two pins together, acting like a closed switch. If you have no way to test for power, the you can just try to have somone hit the starter with a hammer or similar, while you try to crank it over. If it starts after hitting it, you need a strarter. Hope this helps.

1997 cc + Vtec + 9,200 rpm fuel cut = Fun !