I'm starting to think about buying or building a dedicated racecar, possibly starting with a chassis that's retired from some other form of racing. I'm "amused" by other kinds of racing besides hillclimbs (autocross, E production and/or vintage) and ideally would like to find a setup that would be legal for all. But as I look into it, I am puzzled by rollcage specs for open cars. Is there one kind of braced roll hoop setup that will satisfy any & all of these class rules? Do I have to go with a tintop to meet all requirements?

I'm sure somebody else has thought about this and figured it all out...

Rollcages

Re: Rollcages

I dont think anybody has this all figured out, but I wrote the rollcage rule, for NEHA, such as it is:

3. All Roll cages must have horizontal and vertical bars above, ahead,

behind, and to the sides of the plane of the drivers’ helmet. Main hoop

must be braced front and/or back, must have diagonal member(s) or

equivalent within the hoop if spanning more that 3’.

4. Head rest, maximum of 3” behind driver’s head as seated. Any area

reachable by driver’s head must be covered by shock-absorbing material.

5. Roll bar or roll cage must be of adequate construction, i.e.:

Mild steel tubing, minimum diameter and wall thickness of:

1.25” x .120” or 1.38” x .090” under 1500 lbs.

1.38” x .120” or 1.50” x .090” under 2500 lbs.

1.50” x .120” or 1.75” x .090” over 2500 lbs.

6. Plating and brackets should equal or exceed tubing wall. Welded joints in

the basic cage not containing a continuous tube section must be

reinforced with gussets, sleeves, or diagonals so that weld equals 2x tube

circumference. Welds must be fully penetrated, all around the tube.

Minimum weld section should equal tubing wall. Filler/sealer in the weld

area is not acceptable. 4” minimum of weld on (welded) belt/harness

mounts and seat mounts. Alloy (i.e.4130) and titanium cages are

acceptable at the discretion of the tech committee. Entrants should be

prepared to furnish material certification and the credentials of the

welder, current applicable FIA and SEMA spec cages with documention

are acceptable. Aluminum tubing and any cast or forged fittings are NOT

acceptable.

7. Roll cages must be mounted to the structure of the car at 6 points

minimum. Welded mountings must be socketed, gusseted, or “doubler”

plated. Bolted foot plates must be at least 3x tube area, and use at least

3 grade 5 (or better) bolts each with large washers or “sandwich “plates

8. Cars must have at least 2 sections of side protection. Roll cages must

have at least one bar in the door area. Stock door beam found in most

cars is acceptable as a section, as is a substantial outboard frame rail or

rocker panel.

9. Protection for the foot well area, and from “drive train intrusion”, (as in

3.AA.1) must be incorporated into the chassis/roll cage structure.

Complete stock steel floor is considered adequate.

10. Energy absorbing features must be incorporated into the chassis structure

ahead of the driver’s feet, and to the side of the driver.

Ea. Recommendations for collision protection

1. Bend radii at least 3x tubing diameter, and continuous main hoop(s)

2. DOM, SAE 1020 tubing is recommended for roll cage construction.

3. Tubing larger than specification is recommended.

4. 4 door bars are recommended, as are additional vertical supports plating,

and/or “FIA” gussets in the door bar area.

5. Additional reinforcement (i.e. “Flemke” bar) of front cage posts is

recommended, as is a diagonal member in the roof, a vertical (i.e.

“Earnhardt”) bar in the center of the windshield area, and 45 deg joins in

front frame rails and down tubes (i.e. “Corellis” bars)

6. Cage installation should include significant structural enhancements (i.e.

seam welding, gusseting, plating subframe connection) to the cockpit area.

Cages should be tied in at as many points as possible (our rules

specifically exempt safety equipment from class restrictions)

7. Entrants are urged to research specifications relevant to their particular

car, and to build to or above the highest specification available.

What specific section do you need help with? My fellow "techies" and I are, between us, fairly familiar with the rules for most racing series, and can provide examples if we know what's up....

3. All Roll cages must have horizontal and vertical bars above, ahead,

behind, and to the sides of the plane of the drivers’ helmet. Main hoop

must be braced front and/or back, must have diagonal member(s) or

equivalent within the hoop if spanning more that 3’.

4. Head rest, maximum of 3” behind driver’s head as seated. Any area

reachable by driver’s head must be covered by shock-absorbing material.

5. Roll bar or roll cage must be of adequate construction, i.e.:

Mild steel tubing, minimum diameter and wall thickness of:

1.25” x .120” or 1.38” x .090” under 1500 lbs.

1.38” x .120” or 1.50” x .090” under 2500 lbs.

1.50” x .120” or 1.75” x .090” over 2500 lbs.

6. Plating and brackets should equal or exceed tubing wall. Welded joints in

the basic cage not containing a continuous tube section must be

reinforced with gussets, sleeves, or diagonals so that weld equals 2x tube

circumference. Welds must be fully penetrated, all around the tube.

Minimum weld section should equal tubing wall. Filler/sealer in the weld

area is not acceptable. 4” minimum of weld on (welded) belt/harness

mounts and seat mounts. Alloy (i.e.4130) and titanium cages are

acceptable at the discretion of the tech committee. Entrants should be

prepared to furnish material certification and the credentials of the

welder, current applicable FIA and SEMA spec cages with documention

are acceptable. Aluminum tubing and any cast or forged fittings are NOT

acceptable.

7. Roll cages must be mounted to the structure of the car at 6 points

minimum. Welded mountings must be socketed, gusseted, or “doubler”

plated. Bolted foot plates must be at least 3x tube area, and use at least

3 grade 5 (or better) bolts each with large washers or “sandwich “plates

8. Cars must have at least 2 sections of side protection. Roll cages must

have at least one bar in the door area. Stock door beam found in most

cars is acceptable as a section, as is a substantial outboard frame rail or

rocker panel.

9. Protection for the foot well area, and from “drive train intrusion”, (as in

3.AA.1) must be incorporated into the chassis/roll cage structure.

Complete stock steel floor is considered adequate.

10. Energy absorbing features must be incorporated into the chassis structure

ahead of the driver’s feet, and to the side of the driver.

Ea. Recommendations for collision protection

1. Bend radii at least 3x tubing diameter, and continuous main hoop(s)

2. DOM, SAE 1020 tubing is recommended for roll cage construction.

3. Tubing larger than specification is recommended.

4. 4 door bars are recommended, as are additional vertical supports plating,

and/or “FIA” gussets in the door bar area.

5. Additional reinforcement (i.e. “Flemke” bar) of front cage posts is

recommended, as is a diagonal member in the roof, a vertical (i.e.

“Earnhardt”) bar in the center of the windshield area, and 45 deg joins in

front frame rails and down tubes (i.e. “Corellis” bars)

6. Cage installation should include significant structural enhancements (i.e.

seam welding, gusseting, plating subframe connection) to the cockpit area.

Cages should be tied in at as many points as possible (our rules

specifically exempt safety equipment from class restrictions)

7. Entrants are urged to research specifications relevant to their particular

car, and to build to or above the highest specification available.

What specific section do you need help with? My fellow "techies" and I are, between us, fairly familiar with the rules for most racing series, and can provide examples if we know what's up....

John and Michelle Reed

KSCC Life Member

NEHA # 151

KSCC Life Member

NEHA # 151

- Rabbit Farmer

- Posts: 2260

- Joined: Wed Jun 25, 2003 11:37 pm

- AntiSpam: No

- Location: Earth

- Contact:

Re: Rollcages

It really is a hard question to answer.... some classes in SCCA limit the roll cage bracing for autocrosses (as I understand... could have changed, or I am misinformed); our hillclimb rules requires were posted by John above; track events have other rules, etc. I have an FAA spec cage in my car that is good for our hillclimbs and every track event that I can think of... might be good for Pikes Peak, but unsure about that as their rules are a bit confusing.

Go Fast VW & Audi parts at FastAddiction.com

- RALLY200SX

- Posts: 25

- Joined: Mon Mar 09, 2009 12:49 pm

- AntiSpam: No

- Contact:

Re: Rollcages

I try to "multitask" all my projects. I would suggest the use of DOM tubing - I think all SCCA cages are now required to be the DOM tube

#16 1987 Mazda RX7

- walterclark

- Posts: 1442

- Joined: Sun Feb 08, 2009 12:57 pm

- Location: Dover, MA.

- Contact:

Re: Rollcages

That explains it.Rabbit Farmer wrote: I have an FAA spec cage in my car...

The older I get the better I was.

- Rabbit Farmer

- Posts: 2260

- Joined: Wed Jun 25, 2003 11:37 pm

- AntiSpam: No

- Location: Earth

- Contact:

Re: Rollcages

Opps.... FIA. FAA would require wings or something.

Go Fast VW & Audi parts at FastAddiction.com

Re: Rollcages

If you wanna fly, you gotta burn avgas.....

John and Michelle Reed

KSCC Life Member

NEHA # 151

KSCC Life Member

NEHA # 151

Re: Rollcages ; Examples?

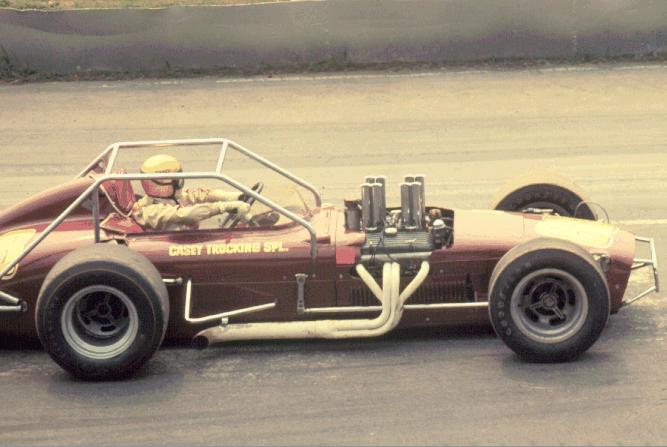

Here's a nice example of a retrofit cage on an Indy-style roadster/supermodified conversion.

http://www.retrorockets.org/1/imagelib/oswb0039.jpg

Chrome cages are done by finish welding the cage in the area to be plated, while the welds to the chassis are tacks, the cage is removed, ground and polished, stress relieved, plated, heat treated to remove hydrogen embrittlement, and then welded to the chassis.

http://www.retrorockets.org/1/imagelib/oswb0039.jpg

Chrome cages are done by finish welding the cage in the area to be plated, while the welds to the chassis are tacks, the cage is removed, ground and polished, stress relieved, plated, heat treated to remove hydrogen embrittlement, and then welded to the chassis.

John and Michelle Reed

KSCC Life Member

NEHA # 151

KSCC Life Member

NEHA # 151

Re: Rollcages

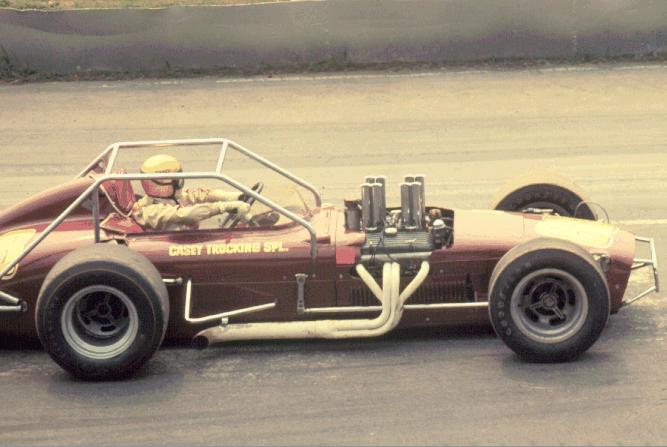

Geoff Bodine's Supermodified/indy car conversion, showing the retrofit rollcage

John and Michelle Reed

KSCC Life Member

NEHA # 151

KSCC Life Member

NEHA # 151